-

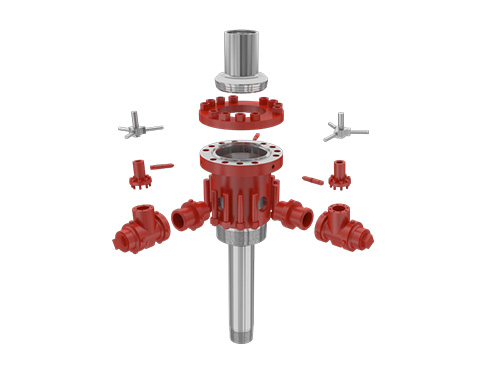

Casing-head

TF series casing head is a device used for connecting and sealing surface casing, hanging and sealing technology and oil-string casing in oil-drilling operation process. In addition, casing head also can monitor casing pipe annulus, annular cement squeeze etc.-Multi-stage Casing Head -Single-stage Casing Head

TF series casing head is a device used for connecting and sealing surface casing, hanging and sealing technology and oil-string casing in oil-drilling operation process. In addition, casing head also can monitor casing pipe annulus, annular cement squeeze etc.-Multi-stage Casing Head -Single-stage Casing Head

TF series casing head could be divided into single-stage casing head and multi-stage casing head according to casing sequence. Double-stage casing head as the main among multi-stage casing head.

TF series casing head could be divided into screw thread type and cava type according to hang modes, divided into rubber seal and soft metallic seal according to sealing mode. It can come into many multiple models if the two cross. We have the design and production capacity of all types hanger.

Rubber seal and metallic seal are interchangeable, in order to fit the high temperature, high corrosion extreme environment and so on. Original metallic seal structure reliability ahead of the domestic and foreign counterparts.

Cava connection and seal at the bottom adopt proprietary technology (patent number: ZL 2013 2 0651234.3), make the perfect combination of high reliability and handleability.

Central spindle and cava hanger are interchangeable under the condition of the flange housing unchanged, easy to deal with all kinds of emergency. Based on the structural improvement, effectively simplify the operating procedure and shorten operation time. After the well completion, it can connect with Christmas tree by oil layer hanger female thread or by end face standard API 6A seal steel ring slot, to realize the isolation between high pressure area and low pressure area of all metallic seal, to avoid rubber ageing problems.

Multi-stage casing head flange is split type in general, easy to deal with all kinds of drilling questions. It also can be made into integral type as user requirement, use for simple and low pressure well location. Casing head can finish all drilling operation by one-step installation, leave out the procedure of dismounting blowout preventer, greatly save drilling time and cost.

Casing Head design, quality control, manufacture and use all according to the API 6A & GB/T22517. And we can design the special casing head as the user's special working condition.

-

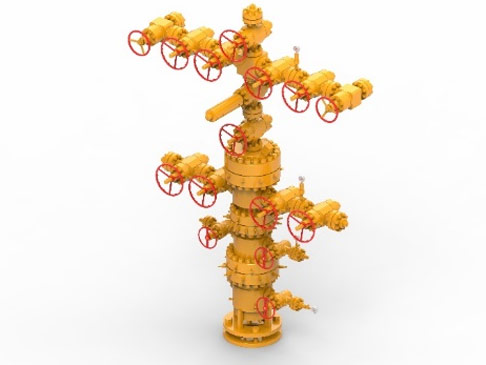

Oil and Gas Christmas Tree

Christmas tree includes tubing head, flat valve, regulating valve, stone, up-flange, screw thread flange, instrument, stop valve and the other components. Christmas tree with casing head together called oil and gas exploitation wellhead equipment. Tubing head installed on casing head, which is the base of oil and gas exploitation wellhead equipment. Tubing head internal pipeline hanger which is used for hanging and sealing the pipeline & sleeve annulus. Casing head connecting with cross valve assembly by up-flange, which form oil and gas recovery channel. If the indicators such as pressure, diameter allowed, can also be used for fracturing and acidizing operation.-KQ Oil and Gas Exploration -KY Oil Exploration

Christmas tree includes tubing head, flat valve, regulating valve, stone, up-flange, screw thread flange, instrument, stop valve and the other components. Christmas tree with casing head together called oil and gas exploitation wellhead equipment. Tubing head installed on casing head, which is the base of oil and gas exploitation wellhead equipment. Tubing head internal pipeline hanger which is used for hanging and sealing the pipeline & sleeve annulus. Casing head connecting with cross valve assembly by up-flange, which form oil and gas recovery channel. If the indicators such as pressure, diameter allowed, can also be used for fracturing and acidizing operation.-KQ Oil and Gas Exploration -KY Oil Exploration

KQ series Christmas tree design, quality control, manufacture and use all according to the API 6A & GB/T22517. And we can design the special equipment as the user's special working condition. -

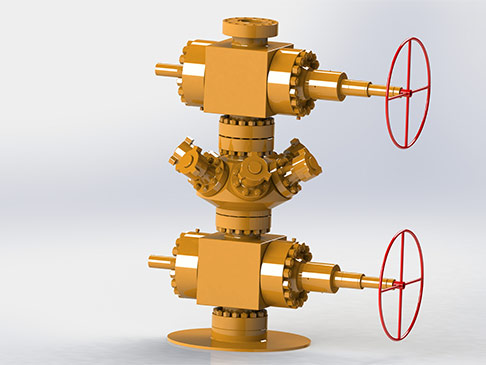

Fracturing Wellhead

The fracturing wellhead device adopts the DFL-R fracturing valve and a patented high-pressure sand control structure, which features high safety and allows for simple and convenient on-site replacement of internal components. The main valve can be operated hydraulically to achieve remote fracturing control. The product has a pressure rating ranging from 70MPa (10,000psi) to 210MPa (30,000psi), a nominal diameter of 4-1/16” to 7-1/16”, a material class of EE to HH, and a performance class up to PR2.

The fracturing wellhead device adopts the DFL-R fracturing valve and a patented high-pressure sand control structure, which features high safety and allows for simple and convenient on-site replacement of internal components. The main valve can be operated hydraulically to achieve remote fracturing control. The product has a pressure rating ranging from 70MPa (10,000psi) to 210MPa (30,000psi), a nominal diameter of 4-1/16” to 7-1/16”, a material class of EE to HH, and a performance class up to PR2. -

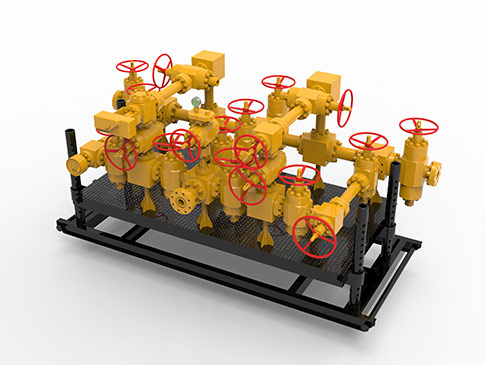

Choke and Kill Manifold

Choke and Kill Manifold is an important well control equipment, mainly used in processes such as drilling, fracturing, surface circulation, and well testing & production. The manifold system monitors downhole pressure, controls back pressure, and performs well killing or blowout bleeding when necessary to ensure wellhead safety. Deshi can design and manufacture onshore drilling manifolds, offshore platform vertical manifolds, mud manifolds, well testing manifolds, etc., according to customer requirements. The products meet the specifications of API 16C, API 6A and NACE MR0175, with pressure ratings covering 3000PSI to 20000PSI and material classes ranging from DD, EE to FF, HH.

Choke and Kill Manifold is an important well control equipment, mainly used in processes such as drilling, fracturing, surface circulation, and well testing & production. The manifold system monitors downhole pressure, controls back pressure, and performs well killing or blowout bleeding when necessary to ensure wellhead safety. Deshi can design and manufacture onshore drilling manifolds, offshore platform vertical manifolds, mud manifolds, well testing manifolds, etc., according to customer requirements. The products meet the specifications of API 16C, API 6A and NACE MR0175, with pressure ratings covering 3000PSI to 20000PSI and material classes ranging from DD, EE to FF, HH. -

Wellhead Valves and Actuators

DUPT can provide various structural types of slab gate valves, throttle valves and actuators. Among them, the slab gate valves include DPF, DFL, DFL-R, DFLD (sand-proof double-seat), DFC and DFK series; the throttle valves cover needle and cage types; the actuators consist of pneumatic actuators and hydraulic actuators (wire-shearable) series.

DUPT can provide various structural types of slab gate valves, throttle valves and actuators. Among them, the slab gate valves include DPF, DFL, DFL-R, DFLD (sand-proof double-seat), DFC and DFK series; the throttle valves cover needle and cage types; the actuators consist of pneumatic actuators and hydraulic actuators (wire-shearable) series.