-

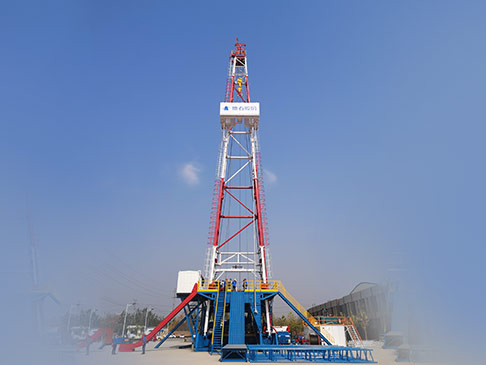

Oil Drilling Rigs

DUPT is a large domestic manufacturer, repairer and supporting supplier of oil drilling rigs, with advanced drilling rig manufacturing equipment and facilities. It can provide seven series of drilling rigs with a well depth range of 1,500m to 9,000m, including various types of rigs such as mechanical drive, DC electric drive, variable frequency electric drive and electromechanical hybrid drive, which are applicable to onshore, desert, marine, vehicle-mounted, low-temperature and rail-mounted scenarios.

DUPT is a large domestic manufacturer, repairer and supporting supplier of oil drilling rigs, with advanced drilling rig manufacturing equipment and facilities. It can provide seven series of drilling rigs with a well depth range of 1,500m to 9,000m, including various types of rigs such as mechanical drive, DC electric drive, variable frequency electric drive and electromechanical hybrid drive, which are applicable to onshore, desert, marine, vehicle-mounted, low-temperature and rail-mounted scenarios. -

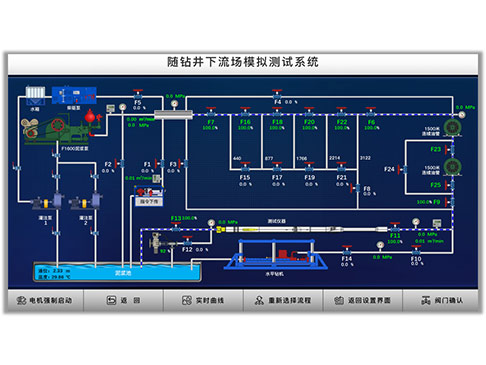

Rotary Steerable System (RSS) Ground Simulation Water Circulation Test System

DUPT has customized and developed multiple sets of ground simulation circulation systems in collaboration with domestic research institutes, providing strong support for the ground testing of rotary steerable systems. Among them, the typical ones include:A 10,000-meter circulation test system, with a pressure of up to 52MPa and a displacement of 90L/S;A 6,122-meter circulation test system, with a pressure of up to 35MPa and a displacement of 90L/S.DUPT has a mature R&D team with rich experience in test system development. It can customize and develop circulation test systems with different parameters according to customers' test requirements to meet the testing needs of various instruments and tools.

DUPT has customized and developed multiple sets of ground simulation circulation systems in collaboration with domestic research institutes, providing strong support for the ground testing of rotary steerable systems. Among them, the typical ones include:A 10,000-meter circulation test system, with a pressure of up to 52MPa and a displacement of 90L/S;A 6,122-meter circulation test system, with a pressure of up to 35MPa and a displacement of 90L/S.DUPT has a mature R&D team with rich experience in test system development. It can customize and develop circulation test systems with different parameters according to customers' test requirements to meet the testing needs of various instruments and tools. -

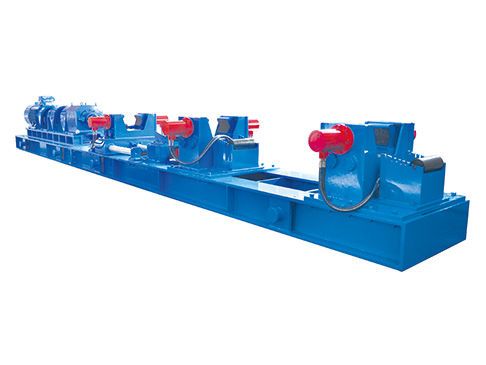

Power Section Test Bench

Power Section Test Bench is designed according to the standard “SY/T5383-2010 downhole motor” and “SY/T5547-2012 operation, maintenance and management for downhole motor”, and can be used to test the fitness between stator and rotor to ascertain the quality condition of both new and repaired power section under test environment. The test bench consists of host machine, circulation system, hydraulic control system and data acquisition&processing system, can test the power section from 1 11/16” to 9 5/8”, and the test data include max torque, differential pressure, etc.-10MDSY -20MDSY -30MDSY

Power Section Test Bench is designed according to the standard “SY/T5383-2010 downhole motor” and “SY/T5547-2012 operation, maintenance and management for downhole motor”, and can be used to test the fitness between stator and rotor to ascertain the quality condition of both new and repaired power section under test environment. The test bench consists of host machine, circulation system, hydraulic control system and data acquisition&processing system, can test the power section from 1 11/16” to 9 5/8”, and the test data include max torque, differential pressure, etc.-10MDSY -20MDSY -30MDSY

The characteristics of Power Section Test Bench are as follows: reliable, safe and easy to maintain; simple and rapid operation; accurate testing data.

-

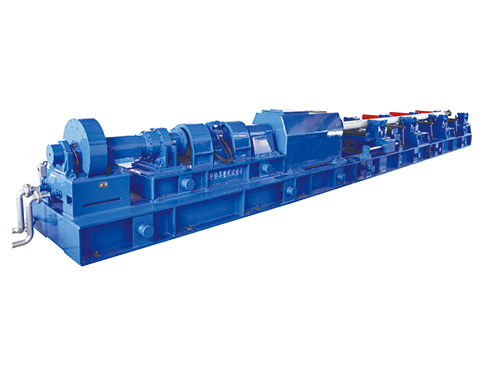

Downhole Motor Test Bench

Downhole Motor Test Bench consists of host machine, dynamical system, circulatory system, hydraulic control system, cooling system, testing system, and can test the performance of downhole motors from 1 11/16” to 11 1/4” under whole-working condition. The test bench adopts advanced control system to implement automatic, semi-automatic or manual testing on loading torque, adjusting flow rate, collect the data such as torque, rotating rate, differential pressure, flow rate, temperature, etc and output the performance parameter table and curve of downhole motor. The test bench fully meet the requirement of manufacturers and oil field to test the performance of downhole motors.-1LZSY Downhole Motor Test Bench -5LZSY Downhole Motor Test Bench -20LZSY Downhole Motor Test Bench -30LZSY Downhole Motor Test Bench

Downhole Motor Test Bench consists of host machine, dynamical system, circulatory system, hydraulic control system, cooling system, testing system, and can test the performance of downhole motors from 1 11/16” to 11 1/4” under whole-working condition. The test bench adopts advanced control system to implement automatic, semi-automatic or manual testing on loading torque, adjusting flow rate, collect the data such as torque, rotating rate, differential pressure, flow rate, temperature, etc and output the performance parameter table and curve of downhole motor. The test bench fully meet the requirement of manufacturers and oil field to test the performance of downhole motors.-1LZSY Downhole Motor Test Bench -5LZSY Downhole Motor Test Bench -20LZSY Downhole Motor Test Bench -30LZSY Downhole Motor Test Bench

1) We realized the simultaneously test of high speed and big torque on one equipment;

2) We own many measures to damping and isolation, to make the operation smooth and the test accurate;

3) The man-machine function is powerful: automatic, manual, semi-automatic can switch conveniently;

4) Abnormal sound and light alarm, security and mutual lock;

5) It is environmental- friendly, electrical-drived, noise-low and no pollution. -

Hydraulic Breaking Unit

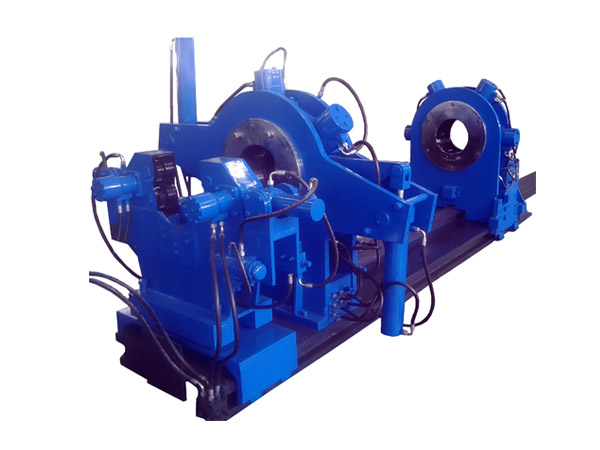

YCZ Type Hydraulic Breaking Unit is an important equipment used for disassembling, assembling and maintaining the thread connection for all kinds of drilling tools, tubular columns and other downhole tools.-YCZ180S -YCZ380S -YCZ380 -YCZ580S -YCZ380LXS

YCZ Type Hydraulic Breaking Unit is an important equipment used for disassembling, assembling and maintaining the thread connection for all kinds of drilling tools, tubular columns and other downhole tools.-YCZ180S -YCZ380S -YCZ380 -YCZ580S -YCZ380LXS

YCZ Type Hydraulic Breaking Unit adopts international advanced multi-cylinder radial synchronous hydraulic clamping way. Clamping force is evenly distributed, workpiece is clamped firmly, and clamping diameter is easy to adjust. Suspension type fast spinner device is adopted to eliminate spinner vibration and greatly improved the spinner speed. Axial drawing device is adopted to provide adjustable axial drawing force. Hydraulic concentrated operations console is adopted, pressure and torque can be read directly, spinner, clamping and moving could be easily executed.