Parameters

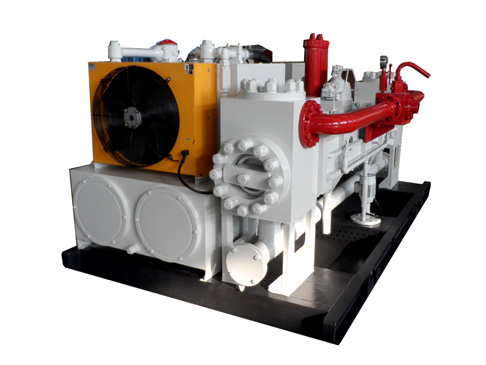

TDB Hydraulic Profile Control Water Plugging Pump is the ideal injection device for water plugging, profile control and polymer, sludge injection when the second or third time extracting oil. It's especially suitable for large amount, long time and constant pressure profile control and water plugging and applicable for many kinds of plugging agents.

Features:

1.Simple structure, reliable performance, easy maintenance, and small weight.

2.Suitable for large amount, long time and constant pressure profile control and water plugging.

3.Large cross-section area of piston, long stroke, low stroke frequency, slow linear speed of piston, and low up and down frequency for suction and exhaust valve.

4.Strong self-suction ability. No need to feed the pump.

5.Low shear rate to protect the properties of plugging agents.

6.The flow rate can be varied according to the bottom pressure (inverse proportion), or manually adjusted in the case of power allowed, according to requirement of actual operating condition. This can protect the oil layer.

7.Long using life of wearing parts, low operation cost.

Features:

1.Simple structure, reliable performance, easy maintenance, and small weight.

2.Suitable for large amount, long time and constant pressure profile control and water plugging.

3.Large cross-section area of piston, long stroke, low stroke frequency, slow linear speed of piston, and low up and down frequency for suction and exhaust valve.

4.Strong self-suction ability. No need to feed the pump.

5.Low shear rate to protect the properties of plugging agents.

6.The flow rate can be varied according to the bottom pressure (inverse proportion), or manually adjusted in the case of power allowed, according to requirement of actual operating condition. This can protect the oil layer.

7.Long using life of wearing parts, low operation cost.

| Name | Parameter | |

|---|---|---|

| Model | TDB-I-25 | TDB-I-35 |

| Electric motor power | 55 | 55 |

| Power | 380V 50Hz AC Three Phase(Allowed tolerance +5%,-10%) | |

| Variable form | Constant power variable | |

| Max flow rate(m³/h) | 10 | 10 |

| Rated pressure(MPa) | 25 | 35 |

| Drift diameter of suction pipe(mm) | Φ127 (5") | |

| Drift diameter of exhaust pipe (mm) | Φ64 (2-7/8")oil pipe box thread | |

| Total Weight(T) | 6 | 6 |

| Length * width * height (mm) | 3500×2200×1500 | |

| Installation mode | Skid-mounted | |

| Applicable medium | All plugging agents for profile control and water plugging: :CSE-1,three-phase foam, Class-G oil well cement, sawdust , swellable particle, sludge, bentonite, polyacrylamide, elm bark powder,cellulose,etc. | |

| Applicable Well | Water well profile control and water plugging, oil well water plugging, polymer flooding and waste oil recycling for Injection station. | |