Downhole Explorer · New Era of Energy: 175℃ High-Temperature MWD (Measurement While Drilling) Tool – The Precise "Navigator" for Deep Earth Exploration

This Issue's Guide: In oil and gas drilling, Measurement While Drilling (MWD) tools act like the "eyes" and "nerves" deep underground, capturing downhole data in real time and completely ending the era of lagging "post-drilling measurement." Whether navigating through complex formations in shale gas wells or targeting tight oil wells with precision, MWD is an indispensable tool for efficient exploration and precise development. As drilling ventures into deeper and hotter territories, high-temperature-resistant MWD has emerged as the "key" to unlocking deep hydrocarbon resources.

175°C High-Temperature MWD: Unlocking Deep Energy Treasures

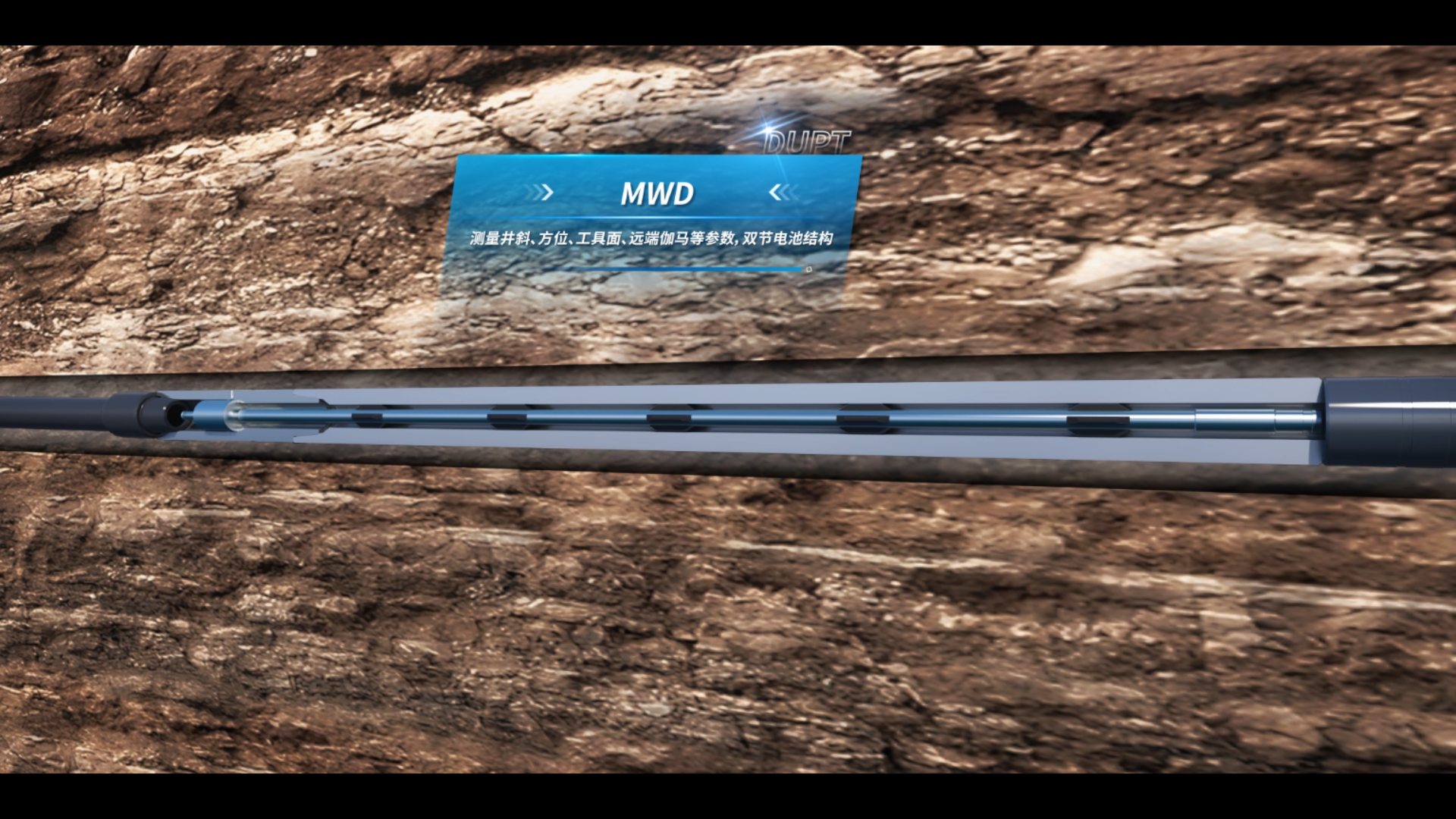

The high-temperature Measurement While Drilling (MWD) tool developed by DUPT takes 175°C as its core performance indicator. Specifically designed for high-temperature downhole environments, it can operate stably under extreme temperature conditions, providing reliable data support for deep and high-temperature well operations.

High-Temperature Components: The "Core Cornerstone" for Stable Instrument OperationThe instrument’s high-temperature performance stems from the rigorous selection and customized design of core components. All key components have undergone high-temperature environment testing and verification, capable of maintaining stable performance under continuous 175°C operating conditions without issues such as data drift or functional failure. From the sensors in the signal acquisition module to the chips in the data processing unit, and further to the components of the power supply system, every component adheres to high-temperature reliability standards. This ensures the instrument can continuously output accurate data even in deep and high-temperature well environments, solving the incompatibility issues of traditional MWD tools in high-temperature wells.

Flexible Extension Subs: Adapting to Multi-Scenario Measurement NeedsTo meet diverse drilling scenarios, this high-temperature MWD adopts a modular design, supporting flexible expansion of various functional subs to achieve "one machine for multiple purposes." It can be equipped with a resistivity sub to accurately identify lithology and oil-bearing properties; an azimuthal gamma sub to clearly depict formation boundaries; a near-bit sub to improve the timeliness of trajectory control; and an engineering parameter sub to comprehensively monitor drilling status and prevent risks. Through the free combination of different subs, the instrument can efficiently adapt to various operation needs—from conventional directional wells to complex horizontal wells, and from shallow exploration to deep development—significantly enhancing the equipment's versatility and overall cost-effectiveness.

30+ Parameter Measurements: Comprehensive and Accurate Data CoverageAs a high-performance MWD tool, its parameter measurement capability directly determines the effectiveness of data support. This 175°C high-temperature MWD can realize real-time measurement and output of more than 30 core parameters, including inclination, azimuth, and magnetic/gravity tool face, covering two major categories: geological parameters and engineering parameters. For geological parameters, in addition to resistivity and azimuthal gamma data obtained through extended subs, it can also measure basic parameters such as natural gamma, providing multi-dimensional data for formation evaluation. For engineering parameters, parameters like inclination, azimuth, and tool face can accurately guide drilling trajectory control to ensure the drill bit advances along the designed path. Meanwhile, combined with parameters such as weight on bit (WOB) and torque, it achieves comprehensive monitoring of the drilling process. The measurement accuracy of all parameters meets high industry standards with low data output latency, providing "timely and accurate" information support for surface decision-making.

Technological Innovation and Reliability: Forging Core Competitiveness

Three Invention Patents: Solid Proof of Technological InnovationIn the R&D process of the high-temperature MWD, we focused on breaking through core technologies. Addressing key challenges such as signal transmission, parameter calibration, and component adaptation under high-temperature conditions, we have achieved a number of independent innovation results and currently hold three invention patents. These patents not only reflect the instrument’s technological advancement but also legally protect the core technologies, providing a solid guarantee for the product’s market competitiveness. They also signify that our R&D capabilities in the field of high-temperature MWD have reached an advanced industry level.

Upper Suspension Mode: Advanced Structure with High ReliabilityThis instrument adopts an advanced upper suspension mode design, offering distinct advantages over traditional lower suspension or other structural forms. With higher structural stability, it achieves more balanced downhole force distribution, effectively mitigating vibration and impact, thus enhancing the reliability of core components. Meanwhile, its structural layout greatly simplifies on-site assembly, disassembly and maintenance processes, significantly improving operational efficiency.

7000m Well Depth Compatibility: Covering Mainstream Deep Earth Exploration NeedsWith the advancement of oil and gas development into deep earth and the continuous increase in well depth, higher requirements have been placed on the instrument’s downhole adaptability. The design specification of this 175°C high-temperature MWD can meet the construction needs of wells within 7000 meters, covering the well depth range of most onshore oil and gas wells and shale gas wells in China. Whether it is conventional wells in medium and shallow layers or deep and high-temperature wells within 7000 meters, the instrument can operate stably, providing strong support for the exploration and development of deep hydrocarbon resources.

R&D Big Data Platform: Building the Closed Loop of Instrument Full-Lifecycle Management

R&D Big Data Platform: Building the Closed Loop of Instrument Full-Lifecycle Management

To fully leverage the technological value of the high-temperature MWD, we have simultaneously developed a supporting big data management platform. It establishes a full-lifecycle data closed loop covering instrument delivery, construction application, and maintenance, forging a "data-driven" new paradigm of equipment management.

Built on Internet of Things (IoT) technology, the platform comprehensively integrates four-dimensional core data: real-time construction data, which dynamically monitors over 30 downhole parameters to support surface decision-making; equipment health data, which achieves fault early warning relying on performance degradation models; historical operation data, which records key performance under different well types, formations, and well conditions to establish a traceable database; and maintenance data, which links maintenance actions with performance feedback to continuously optimize maintenance strategies.

Based on multi-dimensional data fusion, the platform offers four core functions: visualized monitoring and real-time early warning, which enables intuitive grasp of equipment status to prevent unplanned downtime; data traceability and intelligent analysis, which supports working condition review and parameter optimization; full-lifecycle management, which achieves an asset data closed loop from warehousing to decommissioning; and customer collaborative services, which opens data interfaces to enhance cooperation transparency and configuration accuracy.

This platform not only achieves the "aggregation, circulation, and application" of data but also breaks through the full link of "hardware - data - service". It drives the upgrade of the high-temperature MWD from a "single-point equipment" to a "systematic solution", providing solid support for the intelligentization process of deep earth exploration.

From Core to Ecosystem: Strategic Value and Intelligent Evolution of High-Temperature MWD

Against the backdrop of the accelerated global oil and gas exploration towards deep earth, high-temperature, and complex formations, our 175°C high-temperature Measurement While Drilling (MWD) tool, with core advantages including high temperature resistance, strong expandability, full-parameter measurement capability, and high reliability, coupled with the supporting big data management platform, has been applied in the development of complex oil and gas reservoirs such as shale gas, tight oil, and deep carbonate rocks. It effectively helps operators reduce drilling risks, improve reservoir encounter rate, and enhance development efficiency. In the future, Deshi Co., Ltd. will continue to focus on the development direction of "higher temperature resistance, higher precision, and greater intelligence", promote technological breakthroughs in the instrument's measurement precision and temperature resistance level (e.g., 200°C and above), and rely on the AI-enabled platform to achieve intelligent diagnosis and autonomous scheme recommendation. We will continuously improve the comprehensive competitiveness of our products and services, and contribute more strength of "China's Intelligent Manufacturing" to global deep earth exploration.